PCE-428 is a class 2 data logging sound level meter that meets IEC 60651:1979, IEC 60804:2000, IEC 61672-1:2013, ANSI S1.4-1983 and ANSI S1.43-1997 requirements. This portable high-accuracy sound level meter has a large easy-to-read illuminated LCD screen that displays the sound pressure level (SPL) numerically and graphically in real time. The sound level meter calculates the equivalent continuous sound level Leq (LXeq).

- Measuring range: 25 ... 136 db(A)

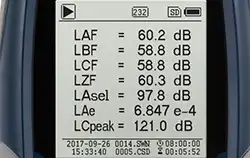

- LXY (SPL), Leq (LXeq), LXYSD, LXSEL, LXE, LXYmax, LXYmin, LXPeak, LXN

- Frequency weighting: A, B, C and Z

- Time weighting: Fast (125 ms), slow (1 sec) and impulse (35 ms), decay (1500 ms)

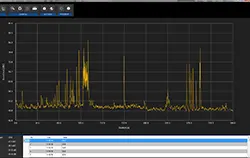

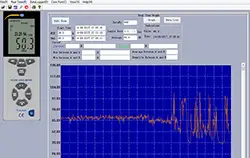

- adjustable data-recording interval from 1 s ... 24 h

- 1/1 octave band filter (optional 1/3 octave band filter upgrade)

PCE-428 is a class 2 data logging sound level meter that meets IEC 60651:1979, IEC 60804:2000, IEC 61672-1:2013, ANSI S1.4-1983 and ANSI S1.43-1997 requirements. This portable high-accuracy sound level meter has a large easy-to-read illuminated LCD screen that displays the sound pressure level (SPL) numerically and graphically in real time. The sound level meter calculates the equivalent continuous sound level Leq (LXeq).

- Measuring range: 25 ... 136 db(A)

- LXY (SPL), Leq (LXeq), LXYSD, LXSEL, LXE, LXYmax, LXYmin, LXPeak, LXN

- Frequency weighting: A, B, C and Z

- Time weighting: Fast (125 ms), slow (1 sec) and impulse (35 ms), decay (1500 ms)

- adjustable data-recording interval from 1 s ... 24 h

- 1/1 octave band filter (optional 1/3 octave band filter upgrade)

- incl. ISO Calibration Certificate

The class 2 outdoor sound level meter PCE-428-EKIT, from the field of environmental measurement technology, is an optimal sound level meter for measurements at workplaces, construction sites, in traffic, airports, etc. The outdoor sound level meter is equipped with an octave band frequency filter. Optionally, the outdoor sound level meter PCE-428-EKIT can be upgraded with a 1/3 octave band filter. The additional kit for outdoor sound measurement makes it possible to measure outdoor noise with a sound level meter over a long period of time, even in the rain.

- Accuracy class 2

- A, B, C & Z frequency rating

- Fast, Slow, Pulse and Peak time

weighting

- Statistics function

- 1/1 octave band included

- 1/3 octave band optional

- incl. outdoor noise level meter kit PCE-4xx-EKIT

- Outdoor measurement of sound and noise

The class 2 outdoor sound level meter PCE-428-EKIT-ICA, from the field of environmental measurement technology, is an optimal sound level meter for measurements at workplaces, construction sites, in traffic, airports, etc.

The outdoor sound level meter is equipped with an octave band frequency filter.

Optionally, the outdoor sound level meter can be upgraded with a 1/3 octave band filter.

The additional kit for outdoor sound measurement makes it possible to measure outdoor noise with a sound level meter over a long period of time, even in the rain.

- Accuracy class 2

- A, B, C & Z frequency rating

- Fast, Slow, Pulse and Peak time weighting

- Statistics function

- 1/1 octave band included

- 1/3 octave band optional

- incl. outdoor noise level meter kit PCE-4xx-EKIT

- Outdoor measurement of sound and noise

- incl. ISO calibration certificate

Noise is defined as a dangerous, annoying or disturbing sound. Thus, noise is a subjective sensation of the sounds affecting us. So, the noise as such is not directly measurable. Through the vibrations of a sound source e.g. voices, loudspeaker membranes, cars, railways, aircrafts, industrial equipment, the vibrations (pressure fluctuations) in the air are generated, which our ears perceive as sound. The frequency of the pressure fluctuations is perceived at the low frequency as low tones and at fast frequency as high ones. When the strength of the pressure fluctuations is increasing, we take it as the sound getting louder. These pressure fluctuations are recorded by the sound level meter and displayed in a measured value in dB (decibels). The decibel range from 0 ... 130 is logarithmic. O dB describes the lower auditory threshold and 130 dB corresponds approximately to the human pain threshold. On the basis of the logarithmic structure, the measured values cannot be simply added, subtracted or averaged.

A Sound level meter is offered with different accuracy classes, different time evaluations and possibilities of the frequency evaluation (filter). As for additional options, a sound level meter with or without storage possibility are available.

As for accuracy, the sound level meter is divided into two classes. A lass 1 sound level meter has a broad frequency spectrum and a very small deviation. For a class 2 sound level meter, the deviation over the complete frequency spectrum may be slightly higher. Since the accuracies to be observed at different frequencies may differ, the accuracy cannot be specified with a fixed deviation number. A sound level meter of class 1 is mainly used for measurements in laboratories or in open-field measurements. Almost all other measurements can be carried out with the a class 2 sound level meter.

The time evaluation of a sound level meter comprises three ranges, based on which the respective average value is formed and displayed. Fast evaluation – duration 125 ms – application for constantly changing noises (traffic noises, neighborhood noise, industrial noise). Low evaluation – duration 1 s – application for constant noise (monotonous hum). Pulse evaluation – duration 35 ms – application for boom noises (shotguns, hammer hits).

For the frequency evaluation, there are several options available for a sound level meter. Frequency evaluation A: measured value dBA. Since a human ear does not perceive all frequencies with the same volume, this rating is adapted to the human ear. Sounds with a frequency between 1000 and 4000 Hz are perceived by people louder than the sounds which are below or above this range. Most measurements carried out by a sound lever meter are performed with this rating (filter). Frequency rating C: measured value dBC. This rating is applied at high sound pressure. DBC is an almost linear frequency evaluation. The memory function can often be presented differently in a sound level meter. Very simple memories store only the Min and Max values of the measured time period. On the next memory level, the values displayed on the sound level meter, with the set evaluation, are stored in preset time intervals (sound level meter logger). A further storage option stores the measured raw data which, with the help of the sound level meter - and PC software, can later be displayed with various frequency evaluations. Logging of the values is also possible in a sound level meter. Since this storage with subsequent evaluation also requires a complex device or PC software, these memories can be found only in higher-priced devices.

Memory functionality and memory capacity differ greatly among sound level meter devices. Very simple memories store only minimum and maximum measurement values. More advanced memories capture and store measurement values in preset time intervals (like a data logger). Another type of memory stores only the raw data. With the help of software, the raw data is evaluated and different parameters are presented for analysis. Since storage with subsequent evaluation requires a complex device or PC software, these memories can be found only in a higher-priced sound level meter.

Accurate sound level measurements can be obtained quickly and easily using a sound level meter with a simple memory. This kind of sound level meter is user friendly and does not require any special knowledge to operate.

For sound level measurements of traffic or neighborhood noise, a datalogging sound level meter that record sound levels over time are ideal. For these applications, a display may not be a necessary component. Instead, a sound level data logger in the form of a USB stick can be used. If the current sound level must be viewed while recording, a sound level logger with a display is required.

For sound level measurements related to occupational health and workplace safety, a class 2 sound level meter can be used. These meters should save the raw data as described above and evaluate the values with different weightings (filters). Furthermore, these devices should calculate time-weighted average values Leq according to the specific logarithm. Throughout Europe, the Leq value is used as a measure for compliance with occupational health and safety regulations. For this measurement, a special Leq sound level meter dosimeter also can be used. Along with a microphone, the dosimeter often is carried on the shoulder of a worker throughout the duration of his or her typical workday. To determine effective noise protection measures, a sound level meter that divide the frequency range of the measuring device into octave bands (11 sub-ranges) or thirds (33 sub-ranges) should be used to present the measured volume per frequency range.

Although typically used in laboratories and more advanced technical applications, a class 1 sound level meter usually divide the frequency spectrum into octaves and third bands.

Among a sound level meter there are various models suitable for different measuring tasks.

One of the most recent standards IEC 61672-1:2002 specifies those limits for the tolerances that should be preferably met by the devices of Class 1 and Class 2. For the Class 1 devices the requirements and limits for the permissible tolerances are just much stricter, which does not mean that devices of Class 2 are bad and unsuitable for measurements. In some applications, Class 2, or what the users could see before, Type 2 (which relates to the old standards) is a minimum requirement and they may be sufficient for a number of measurements. For serious measuring tasks, when it goes, for example, about safety in the workplace, environmental studies, construction of new buildings, Class 1 device is a “must-have” instrument. It has a higher accuracy performance and is considered to be more professional.

The first thought might be that, of course, the other name for the maximum sound level is peak. It is not quite correct. In case of sound level measurement, Peak or Lpeak has nothing to do with Maximum (Lmax).

By using these values, it is possible to create an image or graph of how the noise changes over a certain time. Peak relates more to sound pressure and it cannot be calculated using RMS. It is an instantaneous sound and often it exceeds the maximum value. The measurement of peak is not always necessary and to the point. Nevertheless, in some spheres it is a requirement, for example, for noise level measurement in the workplace.

As well as for many other occupations and activities, there is also a limit for noise exposure over a certain time period.

Noise may really cause pressure and tension. Human ear is a perfect detector for that and when the sound gets too loud, it causes inconvenience and even pain.

Since noise may be of different origin and come from different instruments and sources, a certain system was needed to be able to describe the character of each particular sound / noise and determine its compliance with the official regulations. To develop the methods of reducing the noise is impossible without knowing its characteristics. The frequency at which the noise sounds appear is not always the same, and to exactly determine the intensity of the noise, octave bands have been created. In fact, it is a subdivision of all the frequency range into octave bands, where the upper limit frequency value is always a double of the lowest (the third one is the middle value). A generally accepted range of the middle or centre frequencies goes from 31 Hz to 16kHz (63Hz, 125Hz, 250Hz, 500Hz, 1000Hz, 2000Hz, 4000Hz, 8000Hz). Thus, each of octave bands in the frequency range is characterized by the middle value, from which the upper and lower values may be easily calculated. Depending on the source of noise and location the limit value for the sound pressure level within the octave band of a certain frequency rangy (mostly, from 63Hz to 8000Hz) will be different and it is calculated for each particular case individually.

Sounds precepted by the human ear are very different, they occur at different frequencies, last for different time periods, have different intensity. Due to the existence of the digital measuring instruments sound level and different sound parameters may be measured easily and precisely. Since some sounds do not stay the same and may quickly change, the measuring instrument must react immediately to these changes in order to provide a sufficient level of accuracy and repeatability. Time weightings have been introduced so that to make it possible to compare the measurement of a sound level meter from different producers and of different models. In simple words, it stands for how quickly the sound level meter is able to react to any change in the noise or sounds level. The standard three-time weightings are fast, slow and impulse. Depending on the type of noise, different time weightings may be applied, though fast is the most commonly applied one. Slow – just helps to get a clearer overview of the changes (rise and fall) of the noise. Impulse makes sense only when particular sounds come unexpectedly and are very short-lasting. This weighting is much quicker than fast, especially in its rising phase, and is slow in its falling phase.

Sounds may all be very different and how they are precepted depends on a few factors. For example, human ear is capable of hearing sounds at certain frequencies much better than the at the others, but it does not mean that the sound will not exist, it just does not affect the humans. Such a topical issue, as noise exposure, has led to the development of a variety of noise measuring instruments which are capable of detecting the noise exposure accurately and very precisely. To measure the noise exposure, it is necessary to assess the amount of noise that the human hears, is affected or may be hurt by. Thus, frequency weightings allow carrying out the measurements on the best level, without involving unnecessary data. The standard modern frequency weightings are A, C and Z. the A-weighting is the most common, since it is the closest to how we, humans, perceive the sounds, starting from the lowest of 20 Hz to much higher values of 16 and even 20kHz. That is why such important measurements as LEPd or Leq (see the paragraphs below) are measured based on A-weightings. The national standards and regulations clearly define the recommended noise exposure values based on A-weighting measurements.

C-weighting is applied for sounds which occur at lower frequencies. It actually applies for peak-sound measurements. With the C-weightings those sounds are measured, which the ear may hear, but which are much rare, happen unexpectedly and last very shortly. As a rule, they are very loud and spontaneous, and though the frequency range is wide, the response is much flatter than in the case of A-weighting.

Z-weighting stands for zero frequency weighting (flat frequency response).

In order to systematize the noise and sound measurements, a few main values have been introduced and Leq is one of them. It stands for equivalent continuous sound level. Noise almost never remain on the same level over very long time periods, its intensity may fluctuate depending on activities, machinery used or time of the day. By calculating the Leq value, or LAeq, since mostly it is measured by using the A-weighting, it is possible to make judgements about the average noise exposure. It is a bit more complicated than just a traditional average calculation, since there are logarithms behind noise/sound level measurements, but nevertheless, it gives an exact information whether the noise level in a certain area or in the workplace is satisfactory or unacceptable. The slight, as it may seem to be, increase or decrease in the Leq level, for example, by standard 3 or 5 dB, either requires an immediate significant reduction of the noise exposure duration (cut the time in half), or allows prolonging it (double). For generally noisy environments, the Leq measurement is a significant value for noise situation assessment, for working process planning, for taking corresponding measures (like introduction of protective clothing and accessories, informative seminars).

Noise may be a harmful and dangerous health destructing factor and this is one of the points that every employer should care about. Noise exposure is strictly controlled on the governmental level and the working conditions as well as the devices used for the necessary measurements should meet the standards and official requirements.

In private life, noise is a controversial issue and it often depends on the personal perception. At work, noise daily exposure must not exceed the permissible limits which do not depend on the individual estimations.

The amount of the total noise exposure per day is defined as LEPd. For calculating the LEPd value it takes LAeq (equivalent continuous sound level) at A frequency weighting (the latter is used in the noise measurements, since it in the best way reflects how the human ear perceives the sound/noise) and of course, the duration of the measurement.

The existing regulation take 8-hour working day as standard. The noise level meter is used for carrying out the measurements in the workplace of the workers exposed to noise continuously. The sound level may vary during the day, that is why continuous measurement is required to give an assessment of the LEPd or LEPw (weekly exposure).

The LEPd calculation is required to adjust the working conditions, for example, reduce the duration of noise exposure, provide hearing protection, make the changes on the equipment etc. In general, the louder the noise and the longer the noise exposure, the more the LEPd value grows. The average 80 – 85 dB is the limit which is recommended to focus on. Significant norm exceeds are forbidden and may have aggravating consequences.

For more accurate noise exposure measurement, it is also required to register the peaks, if such occur. LCPeak values, since they are measured with C-weightings, may influence the total noise exposure value, depending on how frequently they occur and which intensity they achieve.

The official standards require regular calibration of the sound/noise measuring equipment. Not depending on the model, the device should present reliable and accurate measurements.

Depending on the frequency of application and specifics of the measurements (private life or working environment check), the noise meters may have different wear-out. To ensure that the device delivers good repeatable results, it is recommended to carry out professional annual calibration, and pre-check before every new application. Besides, it is necessary to remember about correct storage conditions and do not leave the device in appropriate conditions, like very high temperatures or excessive humidity.

It may be quite difficult to fairly evaluate the level of noise in some area, district, at the factory, inside the workshop, at different times of the day etc., because it is rarely continuous and stable. The level of noise may change not only within a day, but within hours and even minutes: it may be very low (almost silence) and then it may be just occasionally interrupted by loud voices, moving vehicles, like motorbikes or cars, or the level of noise may vary depending on the daytime and business of the street, or activity of the workers using noisy equipment, like drilling machines, trucks, jackhammers …

In order to find out the average value, particularly there where the noise emission varies a lot, the Leq measurement is applied.

Each country has its own numbers as for “healthy” norm, and this helps to regulate working process and keep the environment under control (regarding noise). If the value meets the requirements stated in the regulations, it relates normally to 8-hour working day. If the value is below the “normal level”, the number of working hours may be extended, and correspondingly, if it exceeds it – the number of hours of exposure should be reduced.

When it goes about sound / noise level measurement, frequency measurement is mentioned. There are mainly three types of it: A, C and Z. In general, the A Frequency Weighting is applied when it goes about assessment of any possible damage the noise may cause to the ear / hearing, and how the ear react to that noise. Then the values may look like dBA. Evaluation comprising A weightings shows how the ear of a person reacts to the noise usually at low levels.

Since, we can never speak about continuous sound level, and the letter fluctuates tremendously, for carrying our accurate measurements, sound level is measures at all the stages the sound may reach. Thus, C weighting is taken when the Peak Sound level is measured (LCeq / LCPeak). C-weightings concern the reaction of the ear particularly to high noise level.

Another weighting applied nowadays is Z (stands for “0”) which is only “no frequency” weighting (LZeq).

So, in fact, the main point of the frequency weightings to find out the reaction of the hearing system of a human being to a particular sound (particular sound level).

The standard IEC 61672 (IEC 61672-1:2013, IEC 61672-2:2013, IEC 61672-3:2013 and etc.) covers a wide range of norms and regulations regarding sound level measurements. In its three parts, there is a precise specification of required tests that should be carried out to ensure the conformity of the sound level meters to the existing rules, so that not depending on the specifications and class of each particular device, to exclude generation of false results.

To understand what the sound level actually is, it should be made clear first that when the sound appears, it creates a certain pressure, which sometimes lasts only for a very short time and is never permanent/stable. The sound levels change so quickly that it is impossible to register and display all of them in real time. Time weightings have been created to make the process of monitoring and reading the changes happening with the sound level changes, possible and “smooth”.

Nowadays, there are mostly two types used:

The difference between F and S is in the “reaction” to the sound. The response of the Fast is much quicker than the reaction of S to an unexpected sound. Differently they react also when the sound disappears. In the case of F, the level falls down much quicker and a much higher rate (dB/s) than in the case of S.

It has been already mentioned that the instrument should meet strict requirements and norms, not depending on their design, technical specifications, frequencies they are measuring at etc. The point is that the norms also change with the time and though the basic requirements remain the same, the new sets of rules replace the old ones. Sound Level Meter, as any other device, is presented by a big number of different models, which differ in their “possibilities” and correspondingly, in price.

According to the modern regulations (part of IEC 61672-1), Types classification is not valid anymore and instead there are two Classes instead of four types. Class I and Class II sound level meters, in spite of pretty much similar structure and composition, differ from each other in tolerances. No matter, which frequencies it goes about, the tolerances for Class I devices are always much tighter than for Class II. At higher frequencies, the tolerance for the Class I devices gets wider than for the same device at the lowest frequencies, but at each frequency level, the difference between Class I and Class II is evident. The choice of the device should be determined by the application task, and if, for example, it goes about workers health and safety of people, it absolutely makes sense to select devices meeting the Class I requirements and compliant with the latest norms of the International Electrotechnical Commission.

When making assessment about the noise in a certain environment, there may be different parameters, like sound pressure, intensity of the sound, level of the intensity or frequency. Not all sounds can be heard by the human ear, but it does not mean that the unheard sounds have no influence on the person. The frequency between 20 – 20.000 Hz is the range that can be perceived, as against to the ranges below 20 Hz and above 20.000 Hz (infra- and ultrasound correspondingly)

Not only how intense the noise is determines the level of its harmfulness, but also the frequency of the oscillation of the sound pressure per a unit of time. Noise in the workplace is often characterized by the range of sound waves of different frequencies (divided into octave bands). To correctly arrange, for example, the working process, without extreme exposure to noise, it is necessary to know all the noise characteristics, in particular spectral analysis. The whole spectrum for convenience is divided into the octave bands, the noise pressure in which is measured by the noise analyzer. One octave band is when the upper limit value (f2) is a double of the lower (f1). Depending on where and what type of noise is to be analyzed, the octave band is sometimes split into the bands of ½ or 1/3 octave. The latter (f2 / f1 =2 1/3) is more appropriate for noise analysis at the enterprise or where it often goes about technical noises (equipment, working machines). As a rule, the octave and 1/3 octave bands are determined by the geometrical mean value ((16, 31.5) 63, 125 … 8000 HZ). The sound pressure in the octave bands with these geometrical mean values is one of the parameters of the continuous noise that must be carefully controlled with the help of the sound measuring equipment. For each particular case (hospital, school, hotel, restaurant, factory), the standard sound pressure value is different and it should meet the requirements of the health organization.

What is a Sound Level Meter and how does it works?

Watch Video

When using a sound level meter for evaluation or classification of let´s say environmental and traffic noise, it is not only important to have precise equipment. For sure, the sound level meter used should be minimum class II and in calibrated condition, but mainly important is to avoid influences from the surrounding to receive repeatable and trustable results.

What does that mean?

The sound measurement can be influenced by some factors:

1. The Operator

2. Wind and Humidity

3. Temperature and Pressure

4. Vibrations

By touching the housing of the sound level meter, noise can be caused, which influences the measurement results. As well as clothes worn by the operator. Sometimes the body of the operator works as a reflecting surface. To minimize nosie reflections, a sound level meter housing is made in a conic form where the microphone is located. In addition, the sound level meter should be mounted on a tripod so that the operator can be in the background while measuring. Also extension microphone cables can be used to have really remote measurements. Modern sound level meter are equipped with a datalogging function. That makes it more easy to not have the operator to be present during the measurement. It is possible to preset all necessary parameters at the sound level meter.

To avoid or minimize the sound measurement error caused by wind or airflow, a modern sound level meter ever is equipped with a foam ball (sponge around the microphone). This foam ball additionally protects the microphone against dust and small moisture particles. This is very important by doing noise measurements in areas with high relative humidity (>80 %). High humidity rates have influences on the quality of the microphone. For doing sound measurements in very humid or dusty areas, PCE Instruments offer outdoor kits. The sound level meter and the microphone are especially protected for outside measurements.

Every sound level meter has got a technical specification where you can find the maximal temperature the instrument can be used with. As any test instrument high temperature can damage the circuits. But the main point to avoid is sharply changing temperatures, because condensation can be caused and this is a fact to negative influence on the microphone. A smaller cause for sound measurement errors is the ambient pressure. It influences the microphones sensitivity. But the pressure changes taking place must be large(±200 mbar).

When you want to use a sound level meter next to vibration sources, it is recommended to protect the meter or the tripod feed by using anti vibration materials for having more reliable results.

When considering the above mentioned facts, you are able to receive much more stable results by using a sound level meter. For very special sound measurements like peoples sound dose or measurements on protective walls or so, you have to follow the ISO normatives, made for certain measurements:

The traditional unit for sound level is decibel. And one thing about evaluating the level of noise at the workplace or any other situation, is to remember that the conventional rule of doubling (x 2) does not work here. A certain threshold of the human hearing ability is 0. How to double it, if 0 cannot be doubled? In case of decibels, there is a rule to remember that an increase of only a few dB means the loudness / power getting 2-times higher. Thus, if the rule says that the 50dB limit should not be exceeded, and the increase of 10-15 dB seems to be harmless, since it is far from usual double value (100), it is not true and the change of 15 dB is a significant change in reality, which should be taken into consideration. If to speak about acoustics, then each additional 10 dB mean the double loudness/volume (power is doubled at each 3dB, and amplitude – each 6dB).

A sound level meter used for highly accurate measurements, such as reference standards, is referred to as class 1. A class 2 sound level meter primarily is used for testing and inspection to ensure compliance with workplace safety regulations.

Calibration is the control of measurement magnitudes correction for a measuring instrument without intervention in the measurement system, or the determination of the systematic display deviation in relation to the real value of the measuring magnitude.

Since the dawn of measurement, there has been a need to verify accuracy or calibrate. The introduction of International Standards Organization (ISO) 9000 brought about new standards for quality control. As a result, many companies and laboratories must obtain ISO calibration certificates for their measuring instruments. An ISO calibration certificate is a controlled document that confirms that the specific test instruments meet the minimum requirements of the appropriate ISO standard. An ISO calibration certificate can be acquired for most sound level meters offered by PCE Instruments.

As a rule for recalibration, only the results of measurements over time may show when it is appropriate to recalibrate a sound level meter. Very important points to consider also are how and how often the noise level meter is used. If a sound level meter has been used frequently during a short time interval, it may make sense to recalibrate it to make sure that all the functions are correct and the accuracy corresponds. Depending on the environment the sound level meter is used in, the calibration time intervals may also be changed. Laboratory conditions can differ greatly from conditions in the field. Humidity, temperature and contaminants can have a negative influence on the device and recalibration may be desirable.

In reality, many modern devices remain in peak calibration condition. In the past, all instruments required calibration. Nowadays, instruments like a sound level meter are very precise and stable. Of course, in the process of operation, damage is possible, especially with fragile and vulnerable components like microphones. In which case, calibration is applied to restore or verify the accuracy of a sound level meter.

Class I calibration is the most accurate, with a very small uncertainty (or tolerance). Class II allows a bigger deviation. Depending on the sound level meter class, different kinds of calibration can be applied.

For example, for sound:

The period between calibrations of a sound level meter is called a calibration interval. It is the responsibility of each sound level meter user to determine and check the interval between calibrations. PCE Instruments' friendly and knowledgeable technical experts are available to answer any questions related to the process of establishing a calibration interval.

PCE Instruments is a trusted manufacturer and supplier of accurate, reliable sound level meter products. Each test instrument is calibrated and adjusted according to the highest possible quality standards by PCE Instruments itself, or by a first-class calibration laboratory partner.

Handheld acoustic calibrators commonly are available for a class 1 and class 2 sound level meter. To calibrate the meter, the microphone of the measuring instrument is inserted into the calibrator's chamber. For calibration of a class 2 meter, a sound pressure of 94 dB 1000 Hz is generated in the chamber. The class 2 sound level meter is then calibrated based on this value. With class 1 calibrators, the sound level meter is calibrated on two volume levels of 94 dB and 114 dB. An acoustic calibrator is often, but not always, paired with a sound level meter and sold as a set.

DAkkS or ISO certified calibration is possible for almost every sound level meter.

Today it is nearly impossible to find a place in a town or city where there is absolute and total silence. There is simply too much traffic, too many people, factories, plants, railway stations, airports and so on. And yet noise pollution is proven to be detrimental to human health and safety. That is why permissible levels of sound emissions are under permanent control by various regulatory agencies. Any equipment used outside (vehicles, devices, machinery) should meet the requirements of the directives concerning noise and outdoor equipment. Especially in residential neighborhoods, there are particular time periods when work by means of drills and other noisy equipment can be carried out. Even though these sounds are fleeting, their levels are extremely high for unprotected human ears and must be measured by a sound level meter to assess risk and prevent damaging exposure. Problems with noise levels also are experienced by those living in close proximity to railway stations, airports, busy streets, hospitals and fire and police stations. Excessive long-term exposure to high-level noise negatively impacts human health, resulting in hearing damage, raised nervousness, irritability and unstable psychological conditions. Thus, in some areas noise monitoring and control by use of a sound level meter is an essential and mandated task. Noise levels between 120 dB and 150 dB (e.g., airplanes taking off and landing, drilling and sawing of roadways) are dangerous to human hearing and their continuous presence has dire consequences. Perfect noise levels are between 30 dB and 50 dB, though these pleasant levels are sometimes unreachable in today's society.

Physical perception alone cannot determine the severity of noise exposure. You must use a sound level meter to obtain physical measurements. Different people perceive noise in different ways. What is tolerable for some people is unbearable for others. Therefore, the limits of noise exposure are not based on opinion, but on scientific fact. These limits apply to all people exposed to noise, without regard to personal preference. These limits have resulted in many positive changes. For example, workers operating drills are required to wear protective equipment. Whenever possible, airports are built a safe distance away from residential homes. Sirens have been adjusted to alarming yet safe noise levels.

To accommodate diverse sound level measuring needs, PCE Instruments offers a vast array of sound level meters. Our datalogging sound level meters allow for long-term monitoring of noise pollution. Several sound level meters feature impressive ingress protection ratings (IP classes) and can be used in harsh conditions for uninterrupted measuring. For measurements carried out outside, near airports or construction sites, a long-lasting battery pack is ideal so there is no need to search for a power source when measuring in the field. The possibility of mounting a sound level meter on a tripod also exists. The readings collected after a certain period of time may be processed (calculation of LEQ data) and an absolutely clear picture of the noise level in a particular area is received.

It is important to remember that there are limits for noise levels and their duration. If the measurements received with the help of a sound level meter / Leq sound level meter show a discrepancy between the desirable and real values, any problem connected with the noise emission should be solved in a timely manner, so that all requirements for health and safety are met posthaste.

Since there are many parameters by which the noise load is measured and there are various environments with absolutely different limits when it goes about permissible noise dose, noise duration and type of noise, it is quite understandable that the range of measuring instruments for this purpose is also wide. The sound level meters / noise analyzers differ not only in design, but also in the level of the accuracy of the measurements provided. The choice of the device should be relevant with the application purpose. Requirements to noise are all covered by the ISO standards and WHO norms, and the measuring instruments used for the control should correspondingly comply with them. There may be a slight difference, depending on the statute of which Institution is to be followed.

According to IEC, there are Class I and Class II sound level meters. The others though, point out three types: Type 0, Type 1, Type 2, Type 3. Type 0 is referred to as the laboratory equipment, the measurements carried out with these devise are taken as reference for the other meters. They are also used for calibration of other sound level meters. Even though, sound level meter of this type are highly accurate, the application of them is often not appropriate for many routine measurement, and the sound level meters of other types are provide more than sufficient results. For the checks of hygienic conditions in the workplace, or wherever it goes about the health of people, the devices of Class I / Type 1 are perfect. These meters are almost close to the laboratory equipment; they cover a wide frequency range and demonstrate very small measurement error, which is sufficient for a qualified analysis of a certain environment. The devices of Class II / Type 2 are ideal auxiliary tools for general checks, for evaluation of the noise coming from the operating machines; they find their application in many spheres for monitoring and regular control. Type 3 sound level meters may be used for household applications, for example, for determining the level of noise.

Building acoustics is often, but not only, about protection against unwanted noise in the buildings. Speech intelligibility and sound perception, especially in workrooms and event venues, is also an important topic. The buildings do not always comply with the current standards and guidelines.

High values for the airborne sound insulation of a construction provide good protection against noise entering the room to be protected from outside. The existing sound insulation is determined as sound level difference for interior components according to DIN EN ISO 16283-1 and according to DIN EN ISO 140-5 for exterior components. For this purpose, a defined noise signal is generated in the transmitting room, which is recorded frequency-specifically in the receiving room and in the transmitting room via sound level meters. After correcting extraneous noise and reverberation time, the difference is compared with the specifications, e.g. for dwellings, according to DIN 4109 or VDI 4100.

Impact sound is a special form of structure-borne sound that is generated when people walk on floors. The lower the impact sound level of a construction, the less footstep noise enters into the adjacent rooms. The impact sound level is measured according to DIN EN ISO 140-7. In the transmitting room, the separating ceiling to be measured is stimulated with a standard hammer mechanism. The sound level meter in the receiving room records the incoming signal. In the case of hard floor coverings, the noise level is also recorded in the transmitting room and an airborne sound measurement is carried out. Building services equipment, such as lifts, heating and water installations and electrically operated shutters, also generate structure-borne noise that is radiated into the room via the room surfaces. These noises are recorded with the sound level meter according to the specifications of DIN EN ISO 10052. If the noise is too high due to the impact sound or building services equipment, improvements can be achieved through structural measures for decoupling.

The TA Lärm (TI Noise) (Technical Instructions on Noise Protection), as an administrative regulation to the Federal Immission Control Act, regulates noise immissions that may pose dangers, significant disadvantages or significant nuisances to the general public or the neighbourhood. The TI Noise specifies immission guide values for immission locations outside and inside buildings. The requirements for protection against external noise increase with the need for protection of the neighbourhood. For sports and leisure facilities, separate criteria are determined in the Sports Facilities Noise Protection Ordinance (18th BImSchV) and the Recreational Noise Guideline. Traffic noise on roads, railways and waterways is measured according to DIN 45642 and aircraft noise according to DIN 45643. Construction noise is to be recorded according to the AVV Baulärm (Construction Noise).

The sound level meter can be used to check whether noise from one's own installations has an impermissible impact on the neighbourhood or whether the noise from the surroundings exceeds the permissible limits. Even if values or assumptions from the sound immission prognosis are doubted, recording one's own comparative measurements can be useful before commissioning an expert. As an operator of facilities or as an organiser of concerts or festivals, one is responsible for ensuring that the noise level does not exceed the guideline values. If the sound level meters with analogue output or switching output are used, warnings can be triggered when preset limit values are reached, or noisy installations can be throttled or switched off.

The sound effect of noises is strongly dependent on room geometry and room furnishings. They have a significant influence on the reverberation time. In addition to the suitable sound level meter, a signal generator is needed for the test signals. The sound level meter records how long the test signal reverberates. The measurement procedure is described in DIN EN ISO 3382. DIN 18041 specifies the values for the reverberation times of rooms depending on their size. Group A includes rooms in which speech must be clearly audible over long distances, such as conference or training rooms, while group B includes rooms in which speech must only be clearly understood over short distances.

Mobile measurement is becoming more and more important, because as soon as noises are perceived as unpleasant and very loud, a measurement can be taken directly once or permanently for a certain period of time and, depending on the device, stored on an internal memory. Such measurements are often taken in cities with busy roads for a fixed period of time and stored. Afterwards, it can be assessed in peace and quiet whether it is possibly too noisy and where countermeasures need to be taken. But also the evaluation of the stress factor in the office or in the private sphere can be disturbed by noise pollution and, in the worst case, even make people ill.

Sound measurements are carried out with different objectives. The respective measurements differ both in the measurement procedure and in the requirements for the sound level meters, as well as in the handling of the measurement results. For the correct determination and use of the measured values, it is important to know and comply with the specifications of the respective standard. There are engineering companies that specialize in sound measurements and verifications and are certified as experts for sound insulation and acoustics. The technicians who have to carry out noise measurements and evaluations in the company that are compliant with standards and directives can acquire the necessary knowledge in training courses lasting several days with application exercises.

DIN EN ISO 16283-1 Acoustics

Measurement of the sound insulation in buildings and of the building components on site

Part 1 Airborne sound insulation

DIN EN ISO 16283-2 Acoustics

Measurement of the sound insulation in buildings and of the building components on site

Part 2 Impact sound insulation

DIN EN ISO 16283-3 Acoustics

Measurement of the sound insulation in buildings and of the building components on site

Part 3 Facade sound insulation

DIN EN ISO 16032 Acoustics

Measurement of the sound pressure levels of building services in buildings

DIN EN ISO 10052 Acoustics

Measurement of the airborne sound insulation and impact sound insulation and of the noise from technical systems in buildings

Short method