£ 157.00

| PCE-TG-NO7 sensor | |

| Measuring range | 0.65 ... 200 mm / 0.025 ... 7.87" (steel) |

| Minimum diameter of pipes | 15 x 2 mm / 0.59 x 0.07" |

| Frequency | 7 MHz |

| Diameter | 6 mm / 0.23" |

| Description | for thin-walled or strongly curved pipes |

| PCE-TG 300-NO7 device | |

| Measuring range | P-E: pulse-echo mode 0.65 ... 600 mm / 0.025 ... 23.62" (steel)" |

| (measurement range varies depending on the sensor) | |

| E-E: Echo-Echo mode 2.50 ... 100 mm / 0.098 ... 2.36" | |

| (only with PCE-TG 300-P5EE sensor) | |

| Accuracy | ±0.04 mm H[mm] (<10 mm); ±0.4 % H[mm] (>10 mm) |

| H refers to the material thickness of the workpiece | |

| Resolution | 0.1 mm / 0.01 mm / 0.001 mm (adjustable) |

| Measurable materials | metals |

| plastics | |

| ceramics | |

| epoxy resin | |

| glass | |

| and all homogeneous materials | |

| Working modes | Pulse-echo mode (fault and void detection) |

| Echo-echo mode (hide layer thicknesses, e.g. paint) | |

| Calibration | sound velocity calibration |

| zero calibration | |

| two-point calibration | |

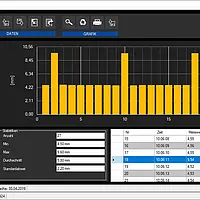

| View Mode | Normal Mode, Scan Mode, Difference Mode |

| Units | mm / inch |

| Data transfer | printing via Bluetooth / USB 2.0 |

| Memory | non-volatile memory with 100 data groups with 100 data sets each |

| Operating time | continuous operation 100 h |

| automatic stand-by mode (adjustable) | |

| auto power off mode (adjustable) | |

| Power supply | 4 x AA battery 1.5 V |

| Display | 320 x 240 pixels TFT LCD color display with brightness adjustment |

| Operating conditions | 0 ... +50 °C / 32 ... 122 °F, ≤80 % RH non-condensing |

| Storage conditions | -20 ... +70 °C / -4 ... 158 °F, ≤80 % RH non-condensing |

| Dimensions | 185 x 97 x 40 mm / 7.2 x 3.8 x 1.5" |

| Weight | 375 g / 13.2 oz |