Bilingual Technical Support (EN / ES)

Public Service, Military and First Responder Discount

30 Day Return Policy

2 Year Warranty

PCE-MWM 240-B VHF-Band Sensor / continuous moisture measurement in bulk (tank / silos)

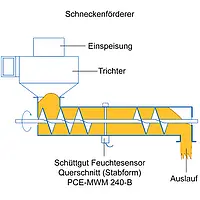

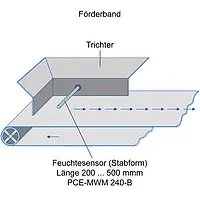

Designed specifically for use in humidity measurement of bulk material, this moisture sensor is installed in bins, silos, troughs, bunkers case, distributors, screw conveyors and on conveyors. Material in bulk or flowing mass, such as dyes, gravel, sawdust, fly ash (mineral), wood chips (surface to 5 cm) feed grain, flour, seed, pastes, ... is smoothly and continuously measurable in the process.

Also

in this humidity sensor, the

measuring principle is based on the use

of waves in the VHF

range. The

unit used for measuring moisture consists

of an electronic box and the moisture sensor

itself. The

sensor part is

manufactured in two versions. Both are

made of AISI 321 stainless

steel (tube diameter 15 ... 30mm), but differ in their structural

design.

Variant 1 (PCE-MWM 240-A): Bow sensor (length 200 mm)

The bow shape makes it extremely robust against shocks and mechanical abrasion. It is fastened by means of adapters on the wall of tanks and silos.

Variant 2 (PCE-MWM 240-B): Rod sensor (length 500 ... 1500 mm)

It is attached like a connecting strut between two container walls.

Variant 3 (PCE-MWM 240-C): Bow sensor (length 200 mm)

A bow sensor that is designed specifically for high conductivity materials like iron ores, coal, and other metals.

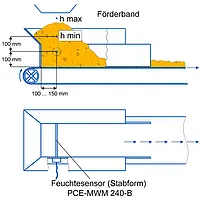

Both sensor types require a

perfect cover with bulk (100mm) in

order to ensure a high measurement accuracy. For this reason, the rod

sensor is often installed in case hoppers.

On the bow shaped sensor additional guiding plates provide sufficient coverage with the material to be measured.

Regulation

of the speed of a

conveyor belt may also be sufficient to always keep a sufficient cover on the humidity sensor. This

is particularly important to

keep the density of the material

to be measuredas

even as possible.

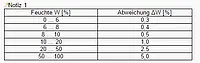

| Measuring range | 0 ... 100 % |

| Maximum permissible error (absolute) | Verified by lab tests |

| Operating temperature range | 0 ... +80 °C |

| Working mode | continuous operation |

| Measuring rate | 1 s |

| Power supply | 24 VDC |

| Current consumption | 200 mA |

| Warm-up time (start-up) | 30 min |

| Outputs | RS485 (Modbus RTU), 4-20 mA [RS485: max. cable length 1000 m; 4-20 mA: max. length 100 m (max. length up to SPS)] |

| Inputs | 2 x digital 24 VDC |

| Dimensions rod sensor | L 500 ... 1000 mm, 15 ... 30 mm dia. |

| Dimensionsbow sensor | L 200 mm, 15 ... 30 mm dia. |

| Dimensions (electronics unit) | 255 х 170 x 60 mm |

| Protection (sensor) | IP65 |

| Protection (electronic unit) | IP54 |

| Dimensions | |

| Rod sensor | 2 ... x kg (depending on the length) |

| Bow sensor | 3 kg |

| Electronics unit | 2 kg |

Please note that we will need further information to provide a final price for supply and fit. We will need to know what materials are to be measured, we will need samples of the material, and we will need a technical drawing showing where the sensor is to be installed.